What EV batteries constitutes of and who is working on them?

Various battery manufacturers are still partnering to provide a huge mass battery. Even investments in EV batteries have risen recently. Car makers like Tesla are still developing their batteries to travel 3000 miles, but the other battery parameters like quick charging capability, more battery capacity are still in demand. The greatest need for batteries is to manufacture EV batteries with improved charging time, longevity, range and the ability to operate at lower temperatures.

Electric vehicle (EV) maker Ola Electric has recently planned to make their own batteries. Major market players, such as BYD Company Limited and LG Chem Ltd, are expected to launch their manufacturing plants on EV batteries in the Asia-Pacific region, primarily in India, China, and South Korea

The players, such as CATL from China, Panasonic from Japan, LG Chem from South Korea, BYD from China, and Samsung SDI from South Korea, are making major contributions to the global EV battery market

What is the need of the hour in electric vehicle battery industry?

One of the most emerging technologies is the solid-state battery, which is similar to lithium-ion batteries, uses a solid electrolyte instead of liquid. Solid-state batteries provide quick charging capability, high power, and lower production costs. They are expected to be available in the market around the year 2030.

Several raw materials involved in manufacturing batteries are also present in sufficient quantity which makes it easier to manufacture and develop batteries. However, the demand is still for the best combination of battery chemistries that can charge in minutes. So, building more miniature battery packs with larger capacities is a challenge in the industry. But fast charging can shorten batteries’ lifespan or overheat them, so most batteries have limited charging speed in order to protect them.

Role of IP in Electric Vehicle Batteries!

Many companies were up till recently building their product portfolios on battery chemistries but the challenges are still in the best combination that are durable, quick charging, more battery capacity etc. The raw materials such as lithium nickel cobalt manganese oxide dominated battery scenario and the demand is expected to increase by factors of 18–20 for lithium, 17–19 for cobalt, 28–31 for nickel, and 15–20 for most other materials in the future.

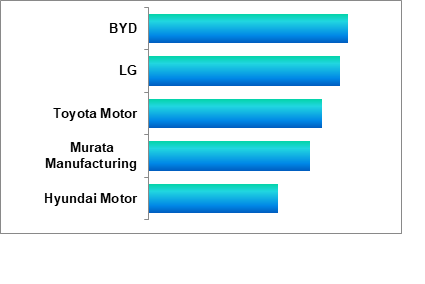

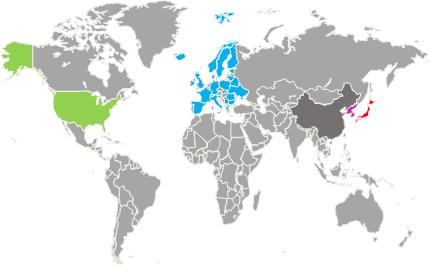

Researchers are focussing on the best anode material since the build-up of electrolyte decomposition on anode can interfere the charging process, stability and performance. Top Players like BYD, LG and Toyota are working on the constructional and battery chemistries of electric vehicles. Geographically China and US holds more share of patents in this technology

Top Jurisdictions working on EV batteries

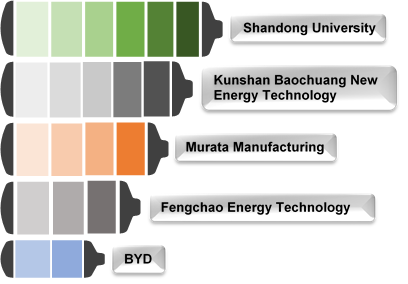

Top Players working on battery chemistries in the past 5 years

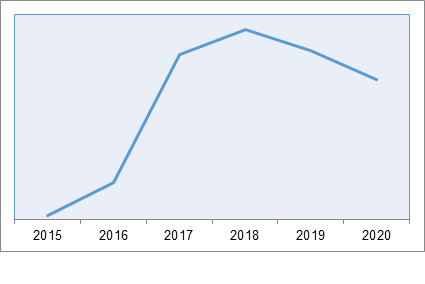

Patent Filing trend over last 5 years on EV batteries

Top player on EV batteries for the past 5 years